Hot–rolled steel coils:

Hot-rolled steel coils, using slabs (mainly continuous casting slabs) as raw materials, heated to form strip steel by rough rolling units and finishing rolling units. The hot steel strip from the last rolling mill is cooled to a set temperature by laminar flow and then rolled into a steel strip coil by the coiler.

After cooling, the steel strip coils are processed into steel plates, flat coils, and slitting steel products through different finishing lines (leveling, straightening, cross-cutting or slitting, inspection, weighing, packaging, and marking, etc.) according to various needs of users.

Production Hot-rolled steel coils

Technical Hot rolled

Width 1219-1500mm

Surface coated or uncoated

Longth Customer's Requirement

Thickness 1.2-20mm

Weight 5-28 tons

Price US $520-640/ Ton

HS Code 7208519000

Application Construction Steel Coil

Cold–rolled steel coils:

Cold-rolled steel coil refers to a steel strip that is directly rolled into a certain thickness at normal temperature and then rolled into a whole coil with a winder.

Compared with hot-rolled steel coils, cold-rolled steel coils have a brighter surface and higher finish, but they also will generate more internal stress and are often annealed after cold rolling.

Product cold rolled steel coil

Thickness 0.3mm-20mm

Width 1000mm,1250mm, 1500mm

Length Customer's Requirement

Technology Cold rolled

Application belt saws, buzz saws, metal band saws, chain saw guides, music box sound pegs,cutters,diaphragm springs etc.

Coil Weight 3-10MT

HS Code 76061199

Galvanized steel coils:

Immerse the thin steel plate in the molten zinc bath to adhere a layer of zinc on its surface. It is mainly produced by the continuous galvanizing process, that is, the coiled steel sheet is continuously immersed in a zinc-melted plating tank to make galvanized steel sheet and alloyed galvanized steel sheet.

This kind of steel plate is also made by the hot-dip method, but it is heated to about 500 ° C immediately after exiting the tank, to form an alloy film of zinc and iron. This kind of galvanized steel coils has good paint adhesion and weldability.

Product name Galvanized steel coils

Thickness 0.12-6.0mm

Width 600mm-1500mm

(usual size:1000mm,1200mm,1250mm,1500mm)

Coil ID 508/610mm

Zinc weight 30-600g/m2

Coil weight 5-8tons

Spangle Mini/regular/big/zero spangle

Price US $ 500-700 /Ton

Application Pre-engineered steel buildings, industrial and commercial roofing and cladding,agricultural buildings, building accessories, light steel framing,construction tubular

HS Code 72104900

Galvalume steel coils:

The galvalume steel coils are an aluminum-zinc alloy structure formed by solidification of 55% aluminum, 43% zinc, and 2% silicon at a high temperature of 600 °.

This alloy is composed of dense quaternary crystals formed of aluminum-iron-silicon-zinc.

Name Galvalume steel coils

Thickness 0.12mm to 1.50mm

Width 600mm--1500mm

Coil weight 3-8 Tons

Coil ID 508/ 610mm

Zinc coating 30-150g/m2

Length Customer's Requirement

Coil ID 508/610 mm

Price $500.00 - $600.00 / Ton

HS Code 7209270000

Application Industrial panels, roofing and siding for painting

PPGI steel coils:

PPGI steel coils are the products that use hot-dip galvanized sheet, hot-dip aluminum-zinc sheet, electro-galvanized sheet as based sheets, after surface pretreatment (chemical degreasing and chemical conversion treatment), one or more organic paints are coated on the surface, followed by baking and curing.

It is also named after the color steel coil plate coated with various colors of organic paint, referred to as color coated coil. The color-coated steel belt uses a hot-dip galvanized steel belt as the base material.

In addition to the protection of the zinc layer, the organic coating on the zinc layer also plays a role in covering and protecting, preventing the steel belt from rusting. Its service life is longer than that of the galvanized belt for about 1.5 times.

Product name Prepainted Galvanized Steel Coil

Material CGCC, DX51D,Q195,Q235

Zinc 20-120g

Thickness 0.13-0.8 mm

Width 600-1250 mm

HS code 721070

Coil weight 3-8tons

Stainless steel coils:

Stainless steel coils are manufactured by hot rolling stainless steel sheets in a reheat furnace. The hot rolling process is carried out at a certain high temperature.

This temperature is known in the industry as the recrystallization temperature, which is between 1,100 ° C and 1,300 ° C, usually depending on the grade of steel used in the manufacturing process. The steel plate is continuously operated by a heating mill, and then the resulting product is appropriately coiled.

After hot rolling and coiling, the stainless steel coil is annealed and pickled to obtain a softer and brighter surface finish without any oxide layers and impurities.

Item stainless steel coils

Standard ASTM GB/T JIS4 ASTM EN.

Material 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S

Technique Hot Rolled And Cold Rolled.

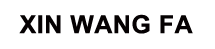

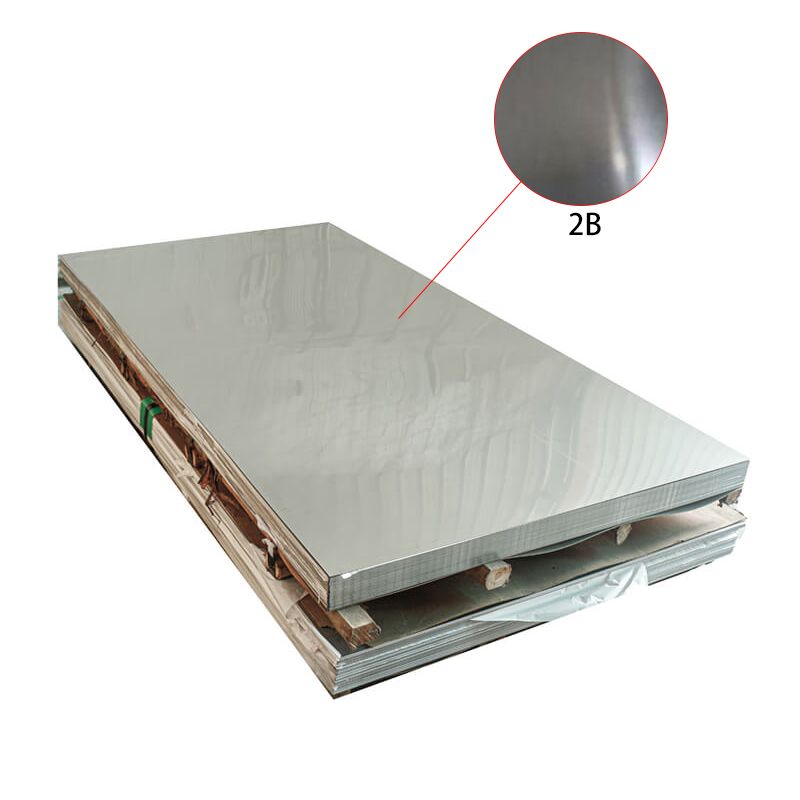

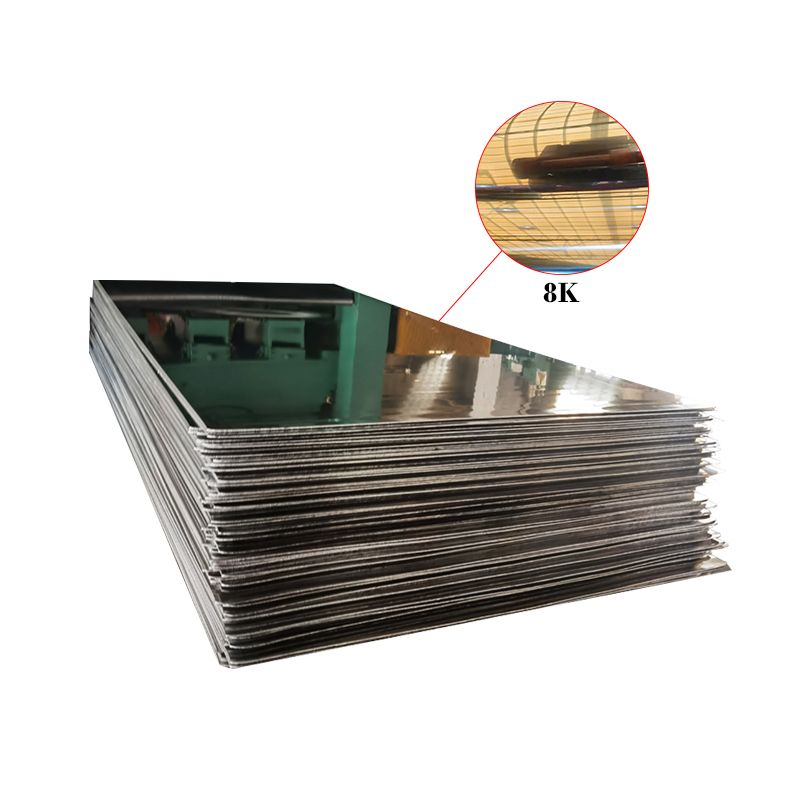

Surface 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror, checkered, embossed

Thickness 0.1~200mm

Width 1000mm, 1219mm, 1500mm, 1800mm, 2000mm

Tinplate:

Tinplate is also known as tinned iron. Tin mainly plays a role in preventing corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, tin solderability, and beautiful appearance of tin in one material. It has the characteristics of corrosion resistance, non-toxicity, high strength, and good ductility.

Name Tinplate coils

Thickness 0.12 to 0.60mm

Width 20 to 1020 mm

Length 600 to 1200 mm

Tin coating 2.8g/2.8g, 5.6g/5.6g, 2.8/5.6,2.0/2.0 gr/m² or according to customer's requirement

Temper T2, T2.5, T3, T3.5, T4,T5 ,DR7,DR7M,DR8 BA & CA

Annealing CA(Continuous annealing) and BA(Batch annealing)

Surface Bright/Stone/Silver finish with passivation treatment; DOS oil

Price 5-24 Tons: US $650

25-99 Tons: US $600

100+ Tons: US $520

HS Code 72101200

Application food packaging, pharmaceutical packaging, daily necessities packaging, instrument packaging, industrial packaging, etc.

FAQ: